| Name of Machinery and/or Equipments |

Manufacture and Model |

Main Specs (size, features etc) |

# of Units |

|

Name of Machinery and/or Equipments

3D CAD

|

Manufacture and Model

CATIA V5

|

Main Specs (size, features etc)

|

# of Units

2

|

|

Name of Machinery and/or Equipments

3D CAM

|

Manufacture and Model

Work-NC

|

Main Specs (size, features etc)

|

# of Units

2

|

|

Name of Machinery and/or Equipments

3D CAD/CAM

|

Manufacture and Model

Others

|

Main Specs (size, features etc)

|

# of Units

4

|

|

Name of Machinery and/or Equipments

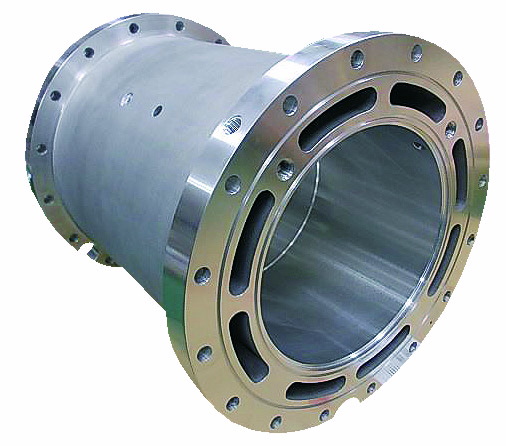

Horizontal machining center

|

Manufacture and Model

|

Main Specs (size, features etc)

Refer to our website for details

|

# of Units

2

|

|

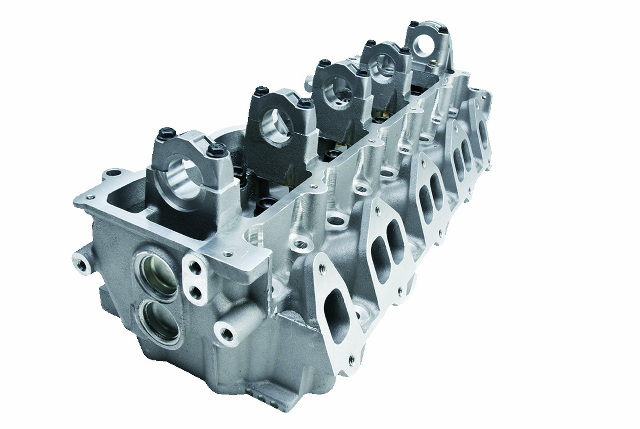

Name of Machinery and/or Equipments

Vertical machining center

|

Manufacture and Model

|

Main Specs (size, features etc)

Refer to our website for details

|

# of Units

10

|

|

Name of Machinery and/or Equipments

NC vertical lathe, NC lathe

|

Manufacture and Model

|

Main Specs (size, features etc)

Refer to our website for details

|

# of Units

4

|

|

Name of Machinery and/or Equipments

Low pressure casting machine

|

Manufacture and Model

|

Main Specs (size, features etc)

1200kg, 850kg, 350kg

|

# of Units

3

|

|

Name of Machinery and/or Equipments

Heat treatment (T4, T5, T6, T7)

|

Manufacture and Model

|

Main Specs (size, features etc)

1500 x 1500 x 2000

|

# of Units

1

|

|

Name of Machinery and/or Equipments

3D scanner

|

Manufacture and Model

FARO

|

Main Specs (size, features etc)

|

# of Units

1

|

|

Name of Machinery and/or Equipments

3D coordinate measuring machine

|

Manufacture and Model

Mitsutoyo

|

Main Specs (size, features etc)

1000 x 900 x 600

|

# of Units

1

|